The purpose of this document is to give background information to the reader about the basics of EMC (Electromagnetic Compatibility), EMI (Electromagnetic Interference), and how it relates to installations in the real world.

As manufacturers across the world continue to develop, innovate, and expand new technologies and products, one important facet of the design and implementation of these new technologies and products is compliance to EMC regulations and standards for different economies and countries. Each of the standards defines the compliance testing and requirements for product families within specific industries and typically describes how to test those products.

RE – Radiated Emissions – A measurement of the over-the-air interference emitted from a product, from both the enclosure (often called the enclosure-port) or the cabling. Limits typically expressed in terms of Volts per meter (dBμV/m) for electric field, or Amperes per meter (dBμA/m).

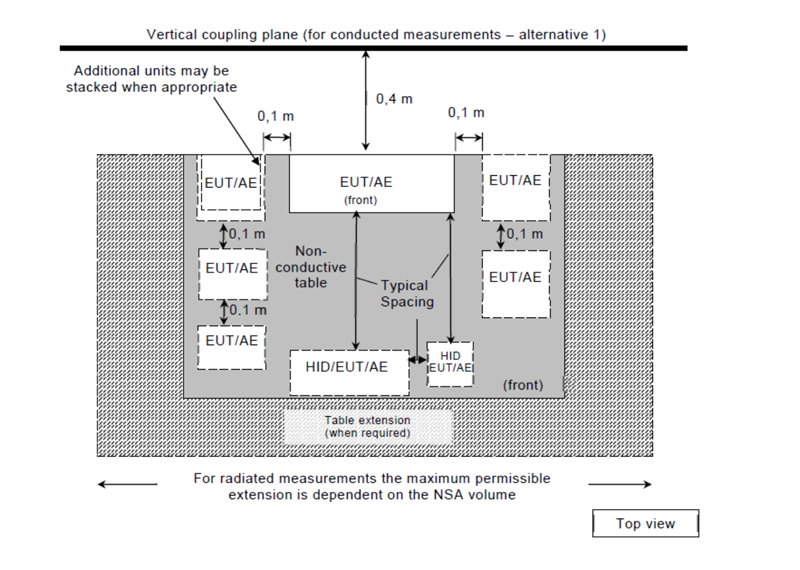

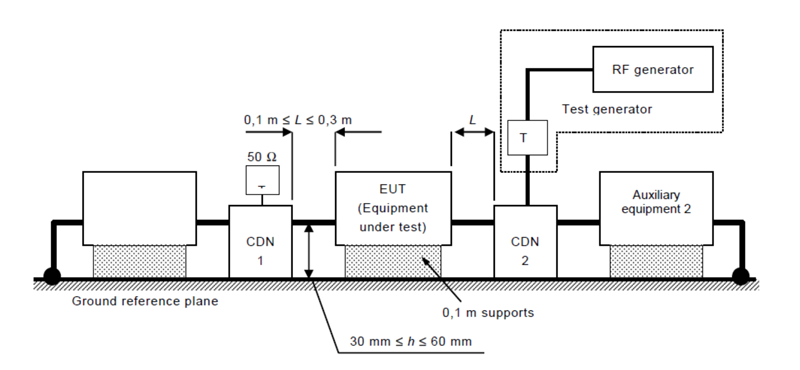

CS or CI – Conducted Susceptibility or Conducted Immunity – The application of a test signal, often imparted onto interfacing cables to EUTs via BCI, CND, EM Clamp, or other means, to observe that the EUT operates acceptably throughout the application of the test.

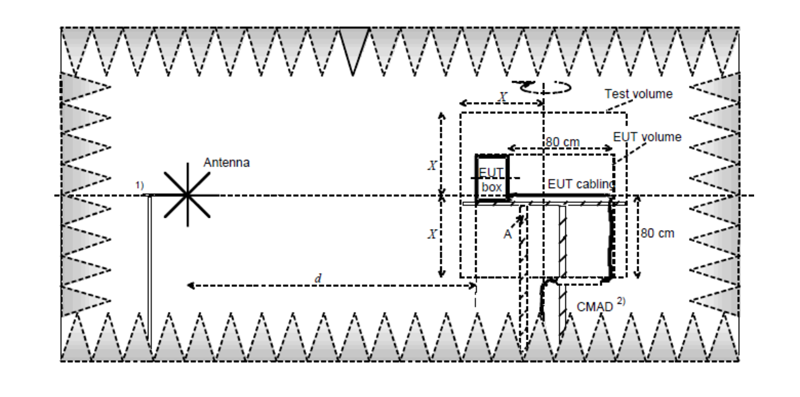

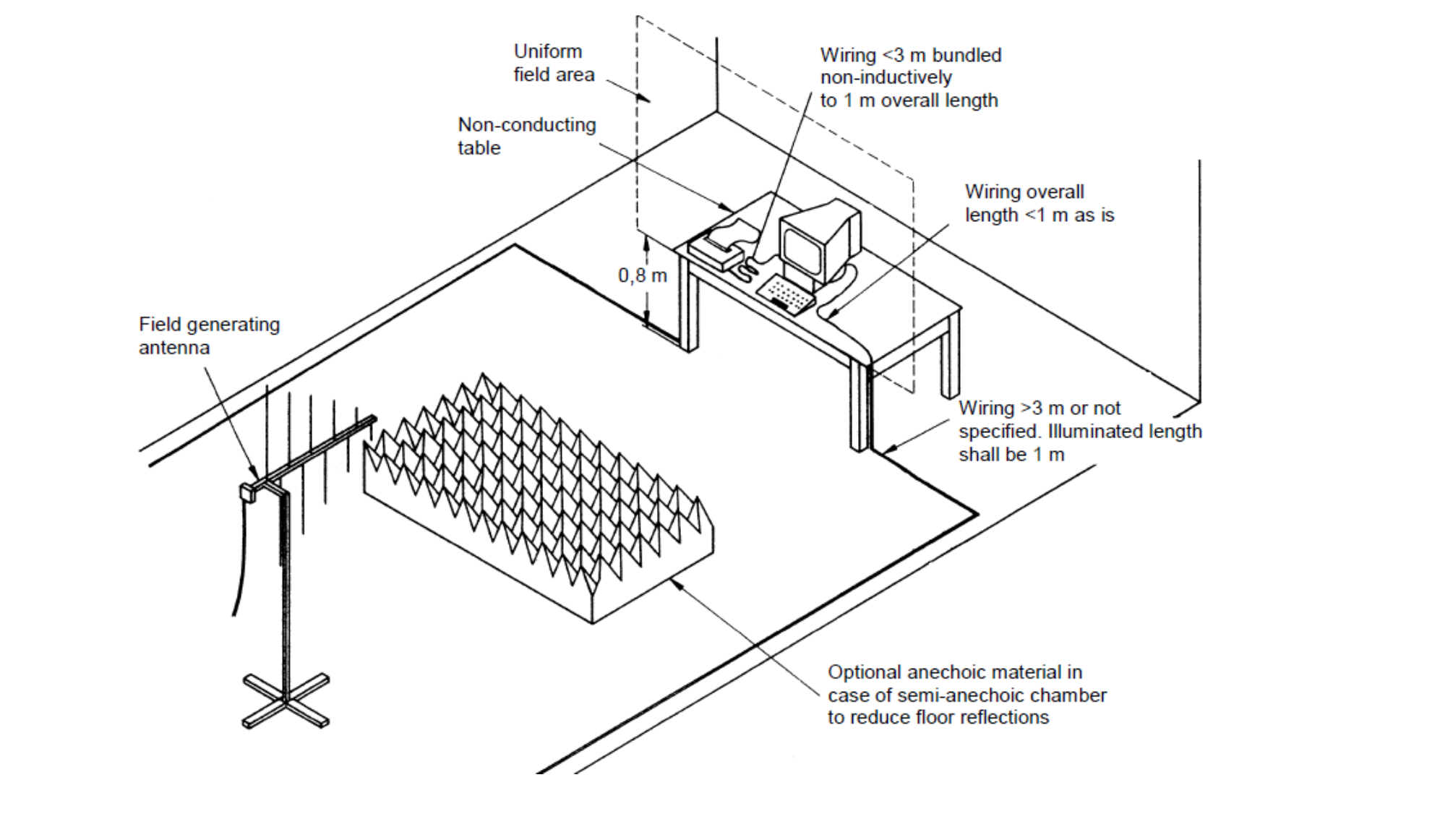

RS or RI – Radiated Susceptibility or Radiated Immunity – The application of a test signal, applied with a test antenna over-the-air, to observe that the EUT operates acceptably throughout the application of the test.

Test Method – The specific test performed. Each test method typically has its own title, such as CS114, RE102, or IEC 61000-4-6, but will fall within the categories of CE, RE, CI, or RI.

Test Standard – A document that defines the requirements, compliance criteria, and limits for a particular product family or industry. For a closer look at test standards, refer to Amplifier Research Application Note #67, EMC Standards Overview. The above definitions of CE, RE, CI, and RI describe the four (4) types of compliance tests performed for pieces of equipment. Within each category, there are two basic phenomena: Continuous and Transient Phenomena.

Continuous test methods typically involve testing within a defined frequency range (for example, 150 kHz to 80 MHz for Conducted Immunity and 80 MHz to 6 GHz for Radiated Immunity). The purpose of testing for continuous phenomena is to ensure that a device or product will operate as intended when a signal is ever-present within its installed environment, or, conversely, not emit a continuous signal that will interfere with other devices environment. For example, a product should always continue to operate when placed within a wireless transmitter’s vicinity, be it Bluetooth, Wi-Fi, or an RFID reader.

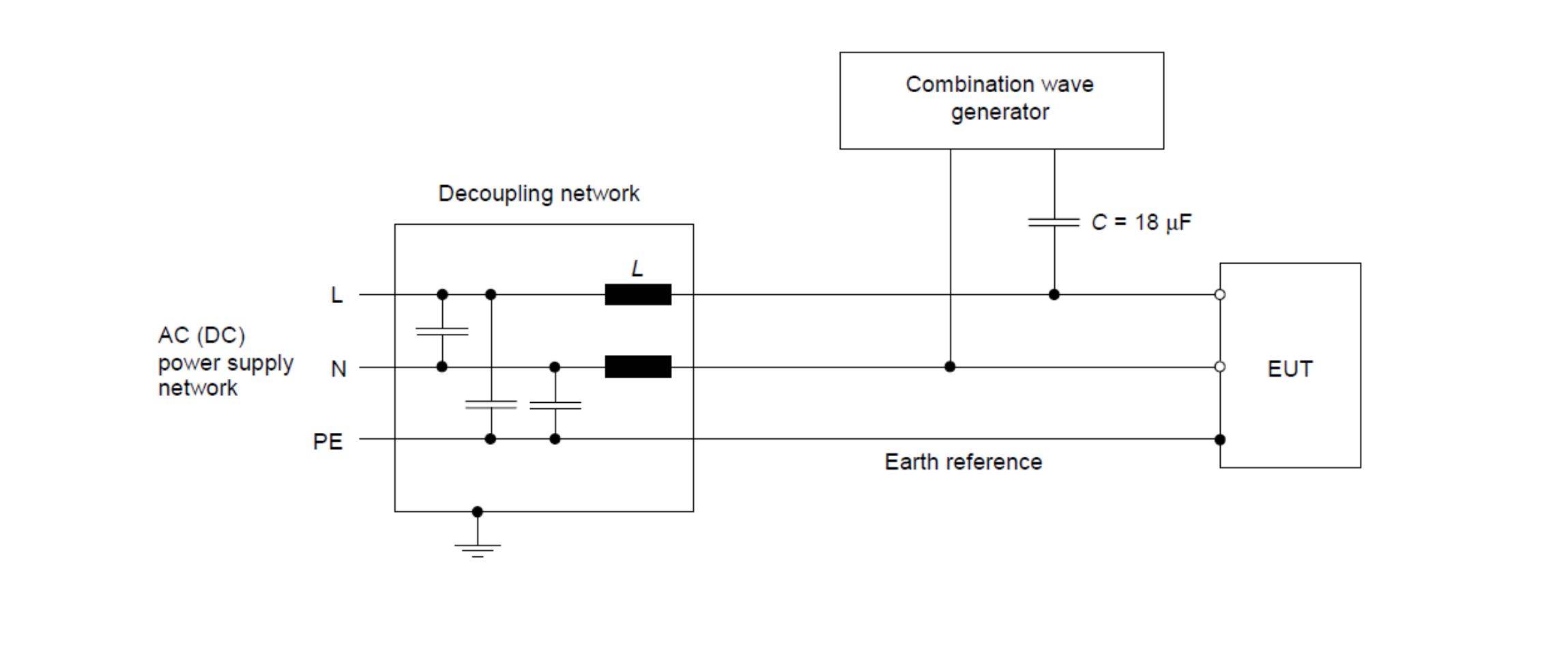

Transient test methods involve testing which simulates phenomena in the real world that are not always present, such as electrostatic discharge (simulating an electrostatically charged human body touching the EUT), surge (simulating a lightning strike of the installed building or location), and electrical-fast transients (simulating load switching of relays). The waveforms defined by the transient test methods are specific to rise time, duration, repetition rate, and source impedance.

During transient testing, an EUT upset or malfunction may be permitted, provided it can return to the previous state or operating mode without user intervention. The compliance criteria for this is dependent on the test standard being tested.

First, there are legal issues. If regulatory requirements aren’t met, then a manufacturer cannot legally sell the product in the country of intention. If a product is sold that doesn’t meet the requirements, the product will likely be removed from the marketplace, fines may be imposed on the manufacturer, and prison time for owners and employees of the manufacturer is a possibility.

Second, EMC testing can and will reveal potential design flaws within a product, where the manufacturer can make a product better, and not just do the bare minimum to meet the requirements. This can alleviate the need for costly recalls and design changes.

EMC is a vast and complex worldwide industry that involves regulatory requirements, different economies, documentation, laboratories, equipment manufacturers, test standards, and test methods. There’s one word that nearly every aspect comes back to, which is the most important word in the EMC dictionary:

Impedance, or resistance, is where the applied limit, test level, waveform, and EUT response are derived. The impedance of a cable will define the amount of RF current that is imparted into an EUT, and the impedance of the shield of the cable will define how much of that RF current is shunted to the ground. The impedance of an antenna will define its effectivity as a radiator, and the impedance of a ground connection, whether it be a shield, a ground strap, or a ground wire, will help define its effectiveness in either shielding for emissions or shunting RF current to ground.

Let’s say that your company has a product that utilizes digital electronics. Depending on where you intend to sell that product, you’ll need to meet regulatory requirements to ensure that the product isn’t going to interfere with other products, or that other products aren’t going to interfere with it. In the United States, the FCC is the government authority that enforces regulations, and the only thing that the US regulates is emissions. For most products, the regulatory requirements are found in Title 47 of the Federal Register under Part 15. If you need to sell into Europe, then you’ll need to investigate testing under the EMC Directive (2014/30/EU) for compliance.

You’ll have to have your product tested, of course. A testing laboratory should be able to help you define what your requirements are, depending on your product type and where you plan on selling it. Once you have the requirements defined, it’s time to get to the test laboratory.

A test laboratory’s services can be used in a few different ways. If you need to see how close you are to compliance, book some evaluation time to run through a few different tests to see where your product stands. Typically, evaluation of the radiated and conducted emissions as well as radiated immunity test methods is where many manufacturers start.

Many companies/manufacturers develop their own in-house testing laboratories to streamline the test phase of product development. This option enables a manufacturer to mitigate problems as they arise, and not be at the mercy of a test lab schedule.

Depending on which test laboratory you choose, or if you’re using an internal or captive laboratory, some regulatory or approving bodies require the test laboratory to be accredited to ISO 17025 before compliance can be declared.

If you’ve done some pre-compliance testing, which can be done on an engineering bench with a small amount of equipment, and are ready for the full-bore test program, contact the test lab for a quotation to test the product for compliance. Once you have a test date, you’re all set.

The above gives a very basic description of EMC, what it is, and why it’s important. The end goal is to ensure that products in the marketplace do not interfere with each other and are immune to interference from other products (within reason). If you have additional questions or need guidance for your requirements, do not hesitate to contact AR’s applications engineers at 800-933-8181.

Title 47 of the Federal Register, Part 15, https://www.ecfr.gov/cgi-bin/text-idx?SID=bd8d7b3d5ac31a5bedaf9455f950fd12&mc=true&node=pt47.1.15&rgn=div5

2014/30/EU, The EMC Directive, https://ec.europa.eu/growth/sectors/electrical-engineering/emc-directive_en

160 Schoolhouse Rd.

Souderton PA 18964-9990 USA

215.723.8181

[email protected]

[email protected]

Contact Us

For an applications engineer call:

800.933.8181

For Customer Service, call:

215.723.0275

For Faxing Orders:

866.859.0582 (Orders Only, Please)

Privacy Policy

Terms of Use

Transparency in Coverage (TCR)

Copyright ©2023 AR Inc.