Systems designed to test for RF susceptibility contain several interconnected RF devices. By necessity, most of these test systems are configured as dynamic turnkey solutions that address more than one of the ever-changing EMC standards. Considering the complexity of the newer EMC standards coupled with the Equipment Under Test (EUT) complexity, the mechanics of simply “running” a standard test can be daunting. While theoretically, one can manually conduct the required immunity tests manually, the amount of time and effort involved is so staggering; manual operation is only feasible when initially configuring a test system, when troubleshooting a system malfunction, or when unique tests are required. The only viable option to this testing dilemma is automating the tests by using a software-driven RF test system controller that provides signal routing through RF switches. While productivity is increased markedly, as a significant decrease in the time required to perform EMC tests, significant benefits also include accuracy and repeatability.

AR RF/Microwave Instrumentation has developed the SC2000 series of RF test system controllers to address the need for flexible automated systems. The SC2000 switch control platform is designed for a multitude of switching applications in RF systems. Each of the main chassis is equipped with five (5), rear-facing, userconfigurable slots. Individual slots or groups of slots can be populated with a variety of SCM series RF switch modules.

The Model SC2000 can be fiber-optically combined with up to seven (7) model SCX2000 expansion units. The model SCX2000 is mechanically identical to the model SC2.

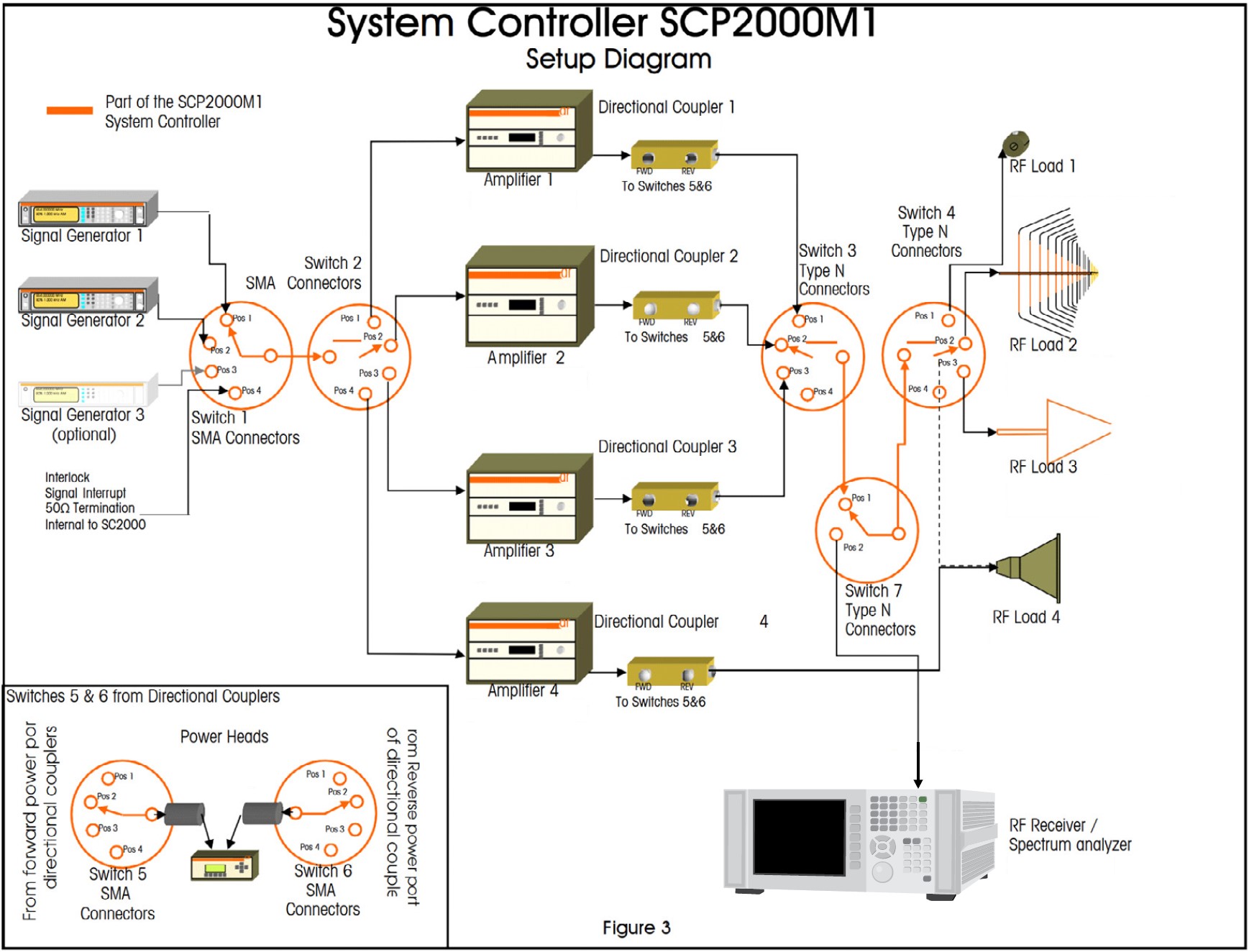

For backward compatibility with the legacy model SC1000, the model SCP2000 was created. This model provides identical switch configuration and operation to the legacy model SC1000 and its modifications (M1– M5).

These switch controller systems can be controlled manually, using the provided color LCD touch display, or remotely, using any of the four provided remote ports (USB, GPIB, RS-232, and Ethernet).

System interlock capability is provided on the Models SC2000 and SCP2000 by sensing switch closures on three independent inputs. Three separate user-definable configurations are provided for times when interlock switch closures are not sensed.

A user-defined “safe” configuration is also provided for use during signal re-routing to assure cold switching of any attached amplifiers and loads. In addition to the three interlock configurations and single “safe” configuration, eight (8) user configurations can be saved and recalled for ease of use in complex systems. This application note details the various uses and configurations of the SC2000 series.

A positive 24 VDC signal along with four (4) open drain outputs and four (4) digital outputs (TTL) are supplied for applications such as external switch/relay control.

The SC2000 System controller has many features built into its design that provide a significant increase in overall productivity, as well as improved test quality and repeatability, thereby providing a considerable savings in time and cost.

Figure 1 is an example of an EMC test setup in its most basic form. Note that there is only one RF path and thus, no RF switching is required.

In Figure 1 the diagram clearly demonstrates the need for additional RF devices to accommodate the higher frequency requirements of today’s EMC standards. The burden of additional test equipment as well as the requirement of multiple RF paths can be mitigated using RF switching. At the very minimum, this system would benefit from the addition of two RF switches.

This is just the beginning of the possible productivity improvements an automated switching matrix provides. By adding just two more switches the requirement for three power meters with six power heads is reduced to a single power meter with two power heads.

While four RF switches seem appropriate for the typical setup shown in Figure 2, additional switches are required for more complex systems. For example, a more complex system would be one where one or more amplifiers need to be switched between two antennas rather than just one, or if the EMC test includes a receiver or spectrum analyzer for emissions testing. As a general rule the more complex the test, the greater the need for RF switching. When configuring an RF system controller, it is best to think ahead and plan for all possible test scenarios to ensure that all conceivable EMC tests can be fully automated.

The design of an RF switch matrix is directly influenced by the RF equipment that is to be switched and is limited by the specs of the coaxial switches selected. The key parameters are frequency range, Max RF power rating, and insertion loss.

From the above review of RF device impact on the RF switch matrix, the two specifications that are key in the selection of RF switches are frequency and power rating. RF switches are limited by theirf coaxial connectors, which are specified for both maximum frequency of operation as well as their power handling capability. Power rating is generally provided at the lower frequency limits with a de-rating curve applied as operating frequency increases. In general, the power handling capability is proportional to connector size and the frequency capability is inversely proportional to size.

For example, a relatively small SMA connector can operate up to 26 GHz with a power rating of 200 watts at 1 GHz while a larger standard Type N connector peaks out at 18 GHz but can tolerate 1000 watts at 1 GHz.

The SC2000 system controller provides switching matrices from DC to 40 GHz at powers ranging from 25 –1200 watts. Higher power and/or higher frequency applications are generally resolved by use of RF devices with waveguide connectors. Since waveguides are very frequency dependent with little overlap between sizes, RF switching is difficult or even unavailable in most cases. For these higher power, higher frequency applications it is best to dedicate antennas to each amplifier. When the frequency does not warrant waveguide connectors, but the power exceeds the capabilities of the SC2000, larger external coaxial switches must be used. As noted above, the SC2000 has a number of open collector outputs and a switchable +24VDC signal that can be used to control these remote high-power switches.

This application note has identified the benefits of automating EMC test systems. While the focus has been on the AR RF/Microwave Instrumentation family of RF test system controllers, it must be noted that automated systems require system software to function. The versatile SC2000 will operate well with emcware® a comprehensive EMC test software package from AR RF/Microwave Instrumentation, or any customer supplied custom software. If you would like to learn more, feel free to contact one of our applications engineers at 800-933-8181, or visit our website at www.arworld.us.

160 Schoolhouse Rd.

Souderton PA 18964-9990 USA

215.723.8181

[email protected]

[email protected]

Contact Us

For an applications engineer call:

800.933.8181

For Customer Service, call:

215.723.0275

For Faxing Orders:

866.859.0582 (Orders Only, Please)

Privacy Policy

Terms of Use

Transparency in Coverage (TCR)

Copyright ©2023 AR Inc.