Menu

Today’s wireless industry is a consumer-driven market. Consumers have high expectations for their smart devices and mobile networks. Not only, has the typical ownership of mobile devices grown from a turnover time of 6 to 12 months to over 2 years, but there is also the expectation that you should be able to get a signal on your phone at any time. A poor user experience can translate to a negative brand standing and a dip in consumer trust in a brand’s products and services. Because of this, manufacturers have been demanding high reliability of the components in their products. 5G technology is set to be installed at many base station locations that will be exposed to extreme outdoor temperatures. In response to these factors, test systems have been developed that allow component manufacturers to assure a high degree of the intended quality.

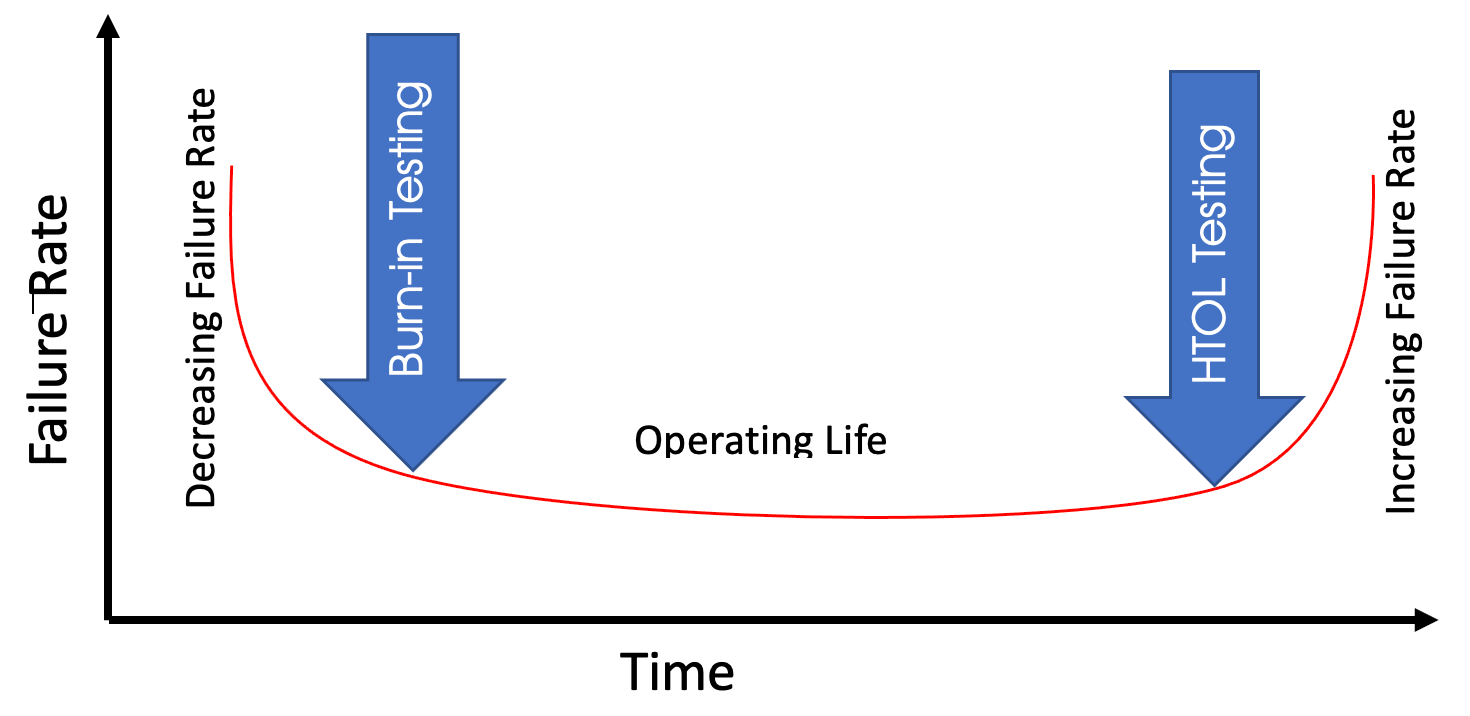

The RF front-end is one section of cellular wireless systems where reliability testing is of particular concern. The RF front-end typically refers to the components directly connected to an antenna such as switches, filters, and amplifiers. These components are exposed to the highest degree of stress in the mobile device or base station. In order to characterize the life expectancy of these parts while regarding this stress, High Temperature Operating Life (HTOL) tests are performed. The manufacturing process requires emerging technologies to be tested at very high volumes; consequently, with production test systems, so that any defects can be screened. Burn-in testing is one such critical production test. These two test methods, HTOL and Burn-in Testing capture the two ends of the reliability characterization graph known as the “bathtub curve” as seen in Figure 1.

The first part of the curve within Figure 1, represents failures as a result of some manufacturing. The final part of the then curve represents the long-term life expectancy.

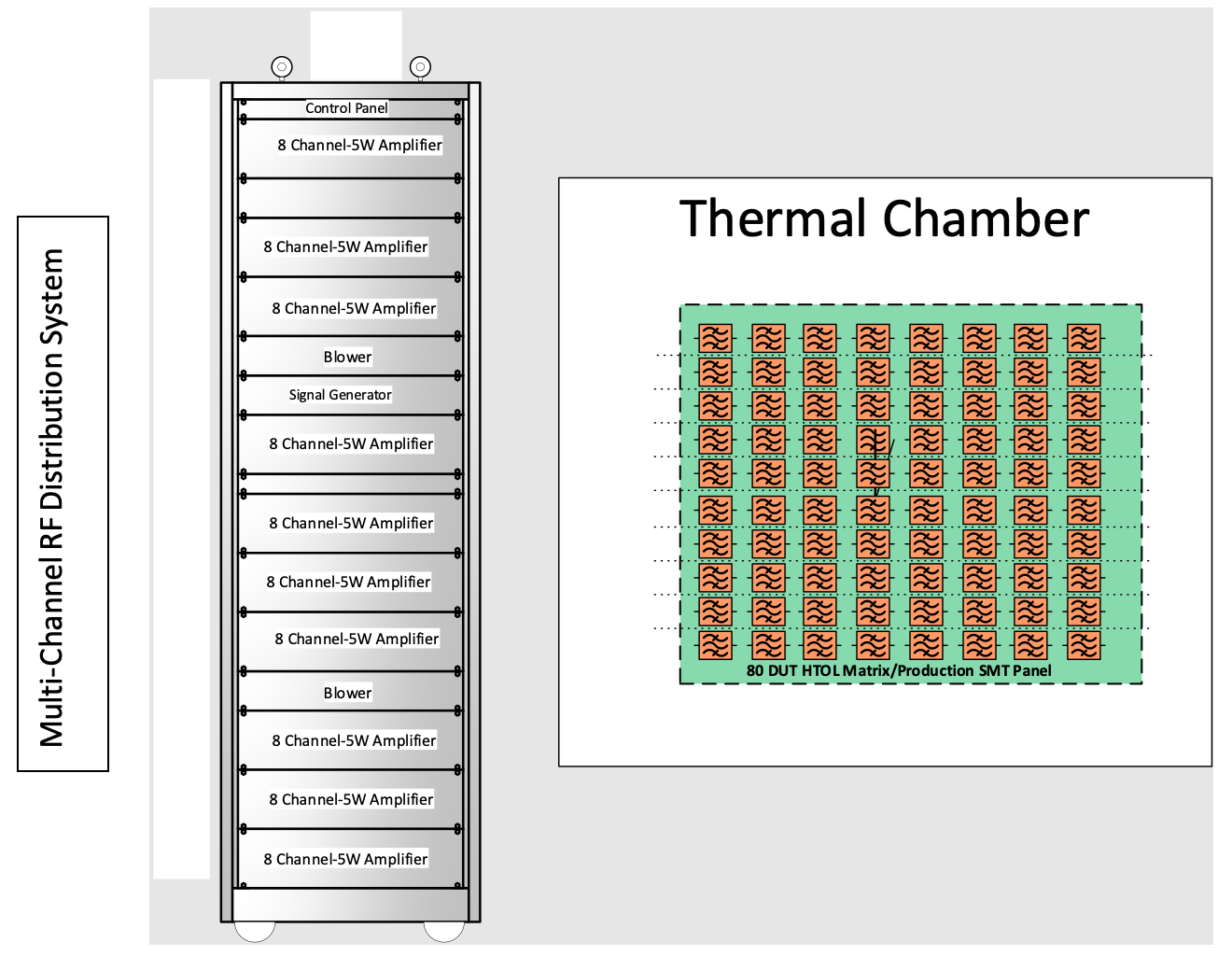

High Temperature Operating Life (HTOL) Testing is a characterization test to be performed on individual components. During the test, acceleration factors are employed to initiate a wear-out failure in much less time than normal life expectancy. Therefore, tightly controlled temperature chambers are employed, as well as an RF source, to stimulate typical RF levels. Many components are typically tested at the same time over a long duration as seen in Figure 2 where a block diagram of an HTOL test system is shown to be capable of testing 80 components simultaneously.

This system is capable of controlling the RF power of each channel over the long-time frame of the test period. The devices under test must be monitored for failure so that RF drive and bias can be removed on a failure while the remaining products continue their test cycle.

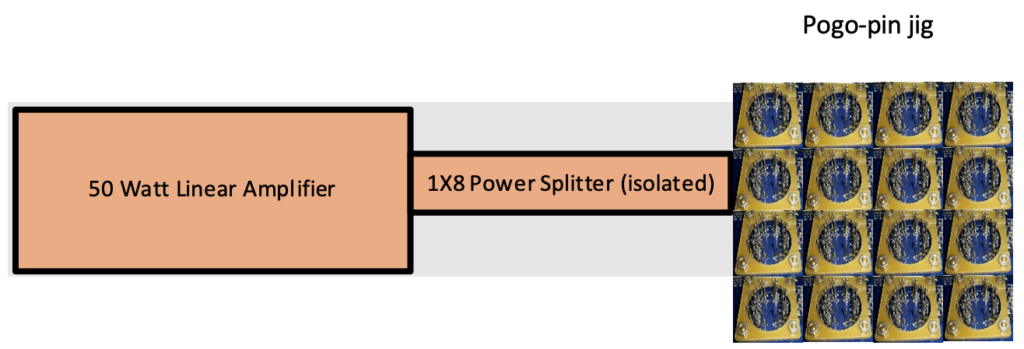

Burn-in Testing is used in production to weed out defective products. This is done by test time translating directly to the cost and then the components are tested in a special platform called a Pogo-pin jig, as seen in Figure 3. A Pogo-pin jig is a specially designed circuit board that holds contact pins to connect to the components. RF devices have the drive power injected via these pogo-pins and an RF distribution amplifier. This system can be customized to provide the required drive power over the desired number of devices to be tested.

As the wireless industry continues to grow, along with the development of emerging technologies, this will translate into the need for reliable test systems with specialized capability. HTOL and Burn-in Testing are the best ways to determine reliability of a component. Both of these tests require RF distribution systems with accurate power control where each channel must be able to apply CW of modulated signals with no distortion. When these testing methods are executed correctly, they will help to ensure the progress of mobile devices and the advancement in the wireless and electronics industry.

160 Schoolhouse Rd.

Souderton PA 18964-9990 USA

215.723.8181

[email protected]

[email protected]

Contact Us

For an applications engineer call:

800.933.8181

For Customer Service, call:

215.723.0275

For Faxing Orders:

866.859.0582 (Orders Only, Please)

Privacy Policy

Terms of Use

Copyright ©2023 AR Inc.